When Real-Time Data Meets AI at the Edge

Manufacturers are finding AI is no longer the answer to automating operations and improving product quality. It’s only half the answer. While AI can increase the defect detection rate by up to 90% over human inspection, it’s useless if manufacturers cannot obtain the information they need when they need it. Without a faster process, they continue to run the risk of unplanned shutdowns and production errors.

“The challenge manufacturers have with AI is actually validating and verifying the return of investment,” says Shunichi Kagaya, Senior Engineer at Hitachi, a leader in digital and IoT solutions. “Manufacturers understand the value of data and they want to use it. But they don’t understand how.”

The Transformation of Industrial AI

AI is already transforming much of the manufacturing industry, but there are still plenty of missed opportunities.

While AI is used to ensure the availability and reliability of equipment, manufacturers are finding they don’t always get insight into the health or status of their machines fast enough.

The data collected from these machines is typically sent to the cloud for analysis, which can delay the results until it is too late. The cloud also does not always provide the security or high-speed and low-latency responses necessary to make actionable decisions.

While #AI can increase the defect detection rate by up to 90% over human inspection, it’s useless if #manufacturers cannot obtain the information they need when they need it. @HitachiGlobal via @insightdottech

Legacy machines can also make it more difficult to obtain data because of their incompatible protocols and siloed systems. Manufacturers traditionally must go through complex preprocessing or data cleansing to even make sense of the information. Again, this delays the ability to take immediate action. This results in production and shipment delays, and even defective products.

“While the customer may understand the need to get the data, they are constrained. Any changes they do make cannot impact the existing production schedule,” says Kagaya. “There is often a tradeoff to be made between the data that is collected, the frequency, and accuracy. You really have to balance all these activities.”

It doesn’t have to be this way.

The Evolution into Edge AI

In conjunction with Intel®, Hitachi has created the Hitachi Industrial Edge Computer CE series Embedded AI model with a built-in image analysis execution platform that leverages Intel’s AI and deep learning technology.

Taking advantage of the Intel® OpenVINO™ Toolkit, the platform can perform image analysis directly on shop floor equipment to quickly alert workers of any product defects or faults. It can monitor multiple production lines and devices simultaneously with remote monitoring capabilities.

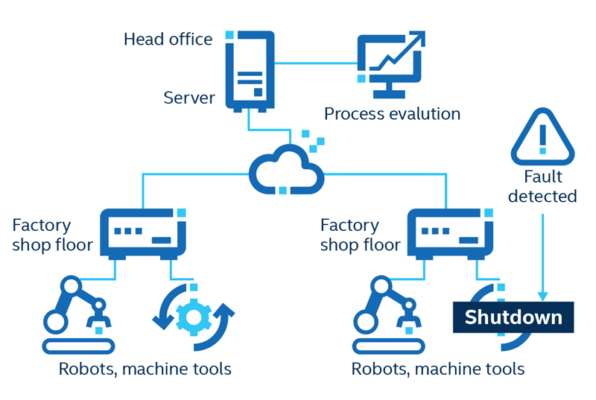

In addition to edge processing, data that may not be critical for immediate analysis can be sent to the cloud for further insights (Figure 1).

“Whether it is ERP or another system, the solution connects the devices, retrieves and formats the data, and then uploads it as valuable information,” says Kagaya. “If we need more processing power and data handling capacity, then we will connect this to the cloud where other AI models can take care of that combined data and execute it. The customer really needs to understand what type of challenge they want to solve and the architecture to achieve it.”

System integrators (SIs) can develop and install containerized applications to extend and add new features or functionality. From a hardware and network point of view, the Industrial Edge Computer CE series can connect to a variety of different equipment to gather data. SIs can customize the solution depending on the use case they are looking to solve.

According to Kagaya, SIs need to have a basic understanding of network protocols as well as familiarity with Python or C++ programming languages to successfully develop their own AI models on top of the Hitachi solution.

At any time, if a manufacturer decides to invest, upgrade, or renew equipment, Hitachi helps customers ensure that the AI model is not affected. “We will work with the customer to really ensure that the model is kept intact, and if there are necessary tweaks required to work with the new data set, we will help them with that as well,” says Kagaya.

Going forward, Hitachi is working on incorporating wireless technologies such as 5G or Wi-Fi 6 into the next series to perform more processing at the edge level. Kagaya says, “Right now, if you send the data to the cloud, have the AI model do the inference, and come back to take the action, that’s not really serving the needs of the equipment in the moment.”

The real challenge in getting this space to take off, according to Kagaya, will be measuring the accuracy of the AI models. He explains that manufacturers typically do not have the patience and expect to see the impact of AI models immediately. But if they can wait to see the results and benefits of this technology, it will be game-changing for the industry.

“The AI models actually provide more accuracy after you start using them more. As the models work on the data continuously, it automatically gets fine-tuned and provides even more accurate results,” he says.

This article was edited by Georganne Benesch, Associate Content Director for insight.tech.