The Software Route to an IPC Upgrade

As factory equipment reaches end-of-life, manufacturing organizations face a crisis. A shortage of spare parts, lagging performance, and software obsolescence put them in a tenuous position. They risk production interruptions due to equipment failure and costly downtime.

But it’s not just about the risks.

There are big opportunities in upgrading machines that drive today’s factories. For example, the move toward IT and OT convergence—the cornerstone of Industry 4.0—requires a more open and connected software-driven infrastructure.

And gaining advantages with new technologies such as computer vision, edge AI, and machine learning depend on high compute platforms and upgraded software environments.

Open, flexible, and high-performance industrial PCs provide manufacturers with options unavailable before: new platforms that empower continuous innovation—enabling businesses to adapt more quickly, stay ahead of global market changes, and increase competitiveness.

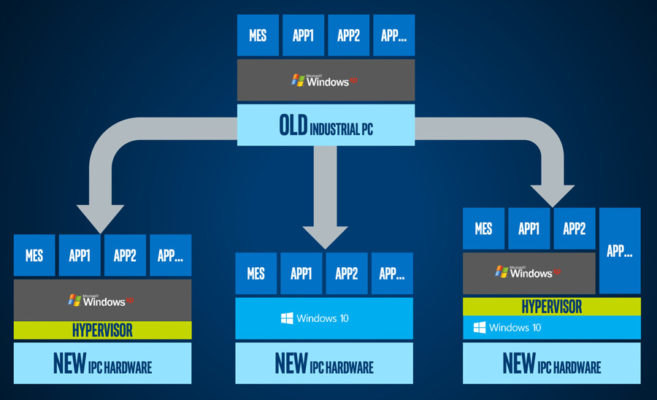

But how do you get there with minimal impact on daily operations? There’s no single right answer. Your path will depend on application requirements, and there are three routes:

- Keep your current software and OS environment

- Keep your current software and run something new side by side

- Deploy a full-blown upgrade of hardware, software, and drivers

We’ll look at all three of these options and why, regardless of the approach, building on top of a virtualized platform provides benefits now and into the future (Figure 1).

Keeping Your IoT Software Platform

The common case for many applications may also be the path of least resistance—a hardware upgrade that requires few or no changes to the existing software environment.

One company is making this option a reality. “You can upgrade to new hardware and still keep your old software environment,” said Jerry Chang, PM Senior Director at DFI. “This is a smaller effort, where factories can just migrate the old system to a new machine. So in many ways it’s the best of both worlds.”

The manufacturer gains more reliability and better performance without having to sacrifice a lot of time and effort to rewrite software. And with an IPC packed with processing power, there’s room to add more capabilities.

The common case for many applications may also be the path of least resistance—a hardware upgrade that requires few or no changes to the existing software environment. @dfi_embedded

Moving an IoT Software Platform to New Hardware

A global supplier of display panel technology partnered with DFI Inc. to seamlessly refresh IPCs in its factories around the world.

For example, one of its factories was experiencing a sharp spike in quality issues related to its aging controllers. Due to the high number of fine-tuned test profiles, the best path forward was to continue using its old XP-based inspection tool software. DFI provided the latest IPC hardware and a virtual machine environment that enabled the manufacturer to keep its existing software set up for a seamless migration.

Chang compared the process to upgrading a 10-year-old PC notebook that’s become too slow and unreliable. “Here’s a similar situation. You want to play your favorite game, but it’s not supported in Windows 10. You can buy the latest and greatest notebook, and with VM technology, you can easily migrate your whole system. When you boot up, you will see the same UI. You log in the same, your wallpaper is the same, everything is the same, except for faster performance.”

To support its needs, the panel manufacturer deployed the DFI RM641-SD, an Intel® verified, “ready to run” next-generation IPC. With pre-installed virtualization software, it was customized to run Windows XP and application binaries associated with the AU Optronics legacy system (Figure 2).

But migrating old software to new hardware requires an “apples-to-apples” upgrade. “If there were five USBs, three cameras, and two LAN ports, we need a system with exactly the same configuration,” said Chang. “So for this use case we designed a board that fits the spec, and ported the customer’s software image.”

When Smart Factories Call for New Software

Some factories are seeing the benefits of consolidating the functions of multiple controllers onto one powerful platform—enabling operational efficiencies and innovation through software. This is a scenario where the panel manufacturer might run both Windows XP and Windows 10-based testing from a single machine—supporting different jobs on different OS environments.

Old and new software would run side by side—maintaining their existing software, I/O, and applications while deploying latest-generation hardware and new software.

But what happens when factory operations call for technology upgrades unsupported by XP? OT engineers face a greater development effort in rewriting applications, drivers, and supporting legacy I/O for Windows 10. The payoff is an IPC set up for the latest and greatest IIoT technologies and more possibilities for continuous innovation.

This was true in the factories where the panel manufacturer builds 4K and 8K LCD panels, which use a very high-resolution camera to do inspections. The system uses video decoding technology not supported by Windows XP—prompting a migration to a Windows 10 environment.

“These are cases where the customer is looking at a whole new controller top to bottom,” said Chang. “They need the machine performance and they need the software. So that’s a complete development project, versus a simple hardware migration.”

Plus they’re set up for the diverse range of AI and machine learning applications being deployed in smart factories. XP is not a friendly option here, where platforms such as Azure IoT Edge and Toolkits like Intel® OpenVINO™ primarily work only with Windows 10.

Beyond Embedded Systems

The panel manufacturer found working with DFI to be a real timesaver. The ability to build flexible, virtualized environments on top of customized IPCs streamlined system upgrades. And services such as porting the software, fine-tuning drivers, and even on-site support assured a smooth transition.

Not only did the manufacturer solve the high-maintenance and malfunction problems of old factory controllers, it extended the life span of equipment and increased productivity. What’s more, the company is set up to innovate more quickly, improve competitiveness, and adapt to global changes.