The Agile Smart Factory: Rapid Turn Ready

COVID-19 has been particularly trying for the manufacturing sector. Worldwide stay-at-home-orders not only prevented workers from staffing factories but also choked the flow of goods to and from facilities as global supply chains slowed to a standstill.

But despite the odds, some manufacturers were able to continue by minimizing fallout from pandemic-driven lockdowns and materials shortages. Overwhelmingly, these operators had Industry 4.0 technology at their disposal that transformed their infrastructure into smart factories.

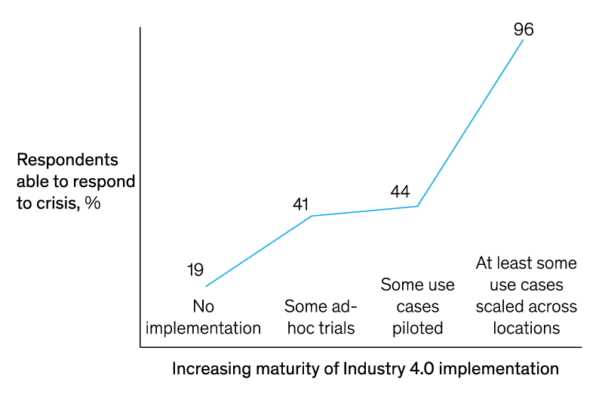

A McKinsey study surveyed leaders from 400 manufacturing organizations. It found that 96% of companies with Industry 4.0 technology scaled across locations were able to effectively respond to the crisis (Figure 1). For example, the report highlights a consumer-packaged goods company that used digital twins to simulate the impact of sudden shutdowns and supply chain disruptions, then optimized operations accordingly.

Conversely, companies without any Industry 4.0 infrastructure struggled through the pandemic. And things don’t appear to be getting any easier. With less cash and fewer engineering resources available in the wake of COVID-19, they risk falling further behind.

This isn’t to suggest these organizations won’t recover. But they must overcome complex digital transformation challenges before they can implement solutions. These challenges include securely connecting the industrial edge to enterprise networks and simultaneously supporting both new and legacy OT systems.

To help manufacturers accelerate development and deployment of Industry 4.0 infrastructure and applications, Intel® designed a suite of industrial-grade digital transformation features into the 11th Gen Intel® Core™ vPro®, Intel® Xeon® W-11000E Series, and Intel® Celeron® processors (previously known as Tiger Lake H).

With enabling tools and #technologies #manufacturing organizations can move their #Industry40 initiatives from strategic planning to tactical implementation. @Portwell_US via @insightdottech

IIoT-on-a-Chip: Tools to Jump-Start Integration

Even though the challenges of IT/OT integration are broad and somewhat abstract, the solutions to them are focused. For instance, coordinating an Industry 4.0 network requires deterministic communications from industrial endpoints to IT servers. But this can’t impact the safe and secure operation of OT endpoints in any way.

Besides scalable computing performance, it’s the integrated safety, security, and real-time features of 11th Gen Core vPro and Xeon W-11000E Series processors that address these needs and make them a game changer for industry 4.0 architects:

- Support for IEEE 802.1 Time Sensitive Networking (TSN) and Intel® Time Coordinated Computing (Intel® TCC) synchronizes device clocks and timestamp packets for deterministic communications.

- Protections for data at rest and code analysis—executed to safeguard local and remote industrial systems via the vPro technology.

- A process framework for more efficient validation and failure analysis via select SKUs outfitted with the Intel® Functional Safety Essential Design Package (Intel® FSEDP).

Of course, these features are only as good as what you can do with them.

To shorten the curve for companies trying to implement digital transformation solutions quickly, manufacturers need a head start in making use of the technologies mentioned above. To accelerate IIoT application development, Intel® frameworks and tool suites maximize the industrial edge computing capabilities on the latest processors.

These development tools address the key technical pillars of Industry 4.0 design—networking, performance, safety, and security.

- Intel® TCC tools provide a framework and APIs that further reduce latency and improve on real-time performance.

- Intel® Edge Controls for Industrial decouples hardware and software infrastructure to simplify the development of high-performance, deterministic IoT applications.

- Intel® Edge Insights for Industrial reference designs combine technologies like Docker containers and the Intel® OpenVINO™ Toolkit to provide real-time, AI-enabled edge analytics and control.

Avert Crisis Today, Optimize for Tomorrow

With enabling tools and technologies manufacturing organizations can move their Industry 4.0 initiatives from strategic planning to tactical implementation. And to do so, operators must contend with a mix of brownfield and greenfield equipment operating on the same infrastructure.

Here, OEMs like Portwell Inc., a leader in Industrial PC and embedded computing, provide automation companies with a forward migration path. Products like its PCOM-B657VGL COM Express Type VI with industry use condition support incorporate 11th Gen Intel Core vPro and Xeon W-11000E Series processors to bring all the networking, determinism, and performance outlined above to manufacturing environments.

The COM Express-compliant devices plug into compatible carrier boards so that legacy systems based can scale. And if more performance or newer features are required in the future, they can be simply swapped out for next-generation modules without having to redesign the entire control system.

The combination of scalable COM Express modules and the highly integrated, Industry 4.0-centric feature set of 11th Gen Intel Series processors are an inflection point for manufacturers amid IT/OT convergence. Without the functionality they provide, organizations may not be able to implement solutions that can mitigate the fallout from crises like COVID-19.

But with them—like the digital twin-enabled consumer packaged goods company—manufacturers can use data as a defense against sudden, drastic change. Or—under more normal circumstances—as an engine of operational efficiency that separates them from the competition.