Rethinking Industrial PCs for Industry 4.0

Artificial intelligence (AI) and analytics are transforming manufacturing, ushering in Industry 4.0. Already valued at $1.1 billion, the industrial AI market is expected to reach $16.7 billion by 2026, according to research firm Markets and Markets.

While there’s enormous potential for the technology, there’s also a challenge. Current industrial infrastructure wasn’t built to provide the flexibility necessary to unlock Industry 4.0’s potential. Workloads are traditionally run on siloed devices that can’t store and analyze data.

“Every big innovation or transformation that’s happened in the past couple of hundred years has had a foundational device that enabled it to occur,” says Adam Berniger, Senior Segment Manager for Industrial PCs (lPCs) for the Intel® IoT Group. “For example, it’s been the steam engine, the personal computer, or the smartphone. The pathway technology that’s driving Industry 4.0 is the industrial PC.”

The modern industrial PC brings together IT and operational technology (OT) to analyze volumes of edge data that can be collected from factory machines and turned into business intelligence. To facilitate the digital transformation, manufacturers are turning to systems integrators (SIs) to be the experts who help them tap into the valuable information on the factory floor.

Industrial PCs: The Vital Connectors

This represents a major opportunity for SIs. “The edge is growing in strength and value,” says Berniger. “There are three emerging themes that center around the edge: intelligence at the edge, convergence of the edge, and connection to the edge.”

Intelligence at the edge includes analytics, insights, and AI. “It can drive smartness closer to where things are done in a factory,” says Berniger. “Use cases can include predictive maintenance and analysis, improving operational effectiveness, and boosting productivity.”

How can SIs succeed in Industry 4.0? For @axiomtek, Industrial PCs are the key. via @insightdottech

Convergence of the edge encompasses OT and IT best practices, processes, devices, functions, and applications. Connection to the edge means connecting unconnected devices both to one another and to the cloud.

Berniger likens the potential of the industrial PC to the smartphone. “Five or 10 years ago, if we were going on a trip, we had a ‘dumb’ phone for making calls or sending text messages,” he explains. “We had a camera to take pictures, and we had to print off a map to know where we were going. We had multiple devices for separate functions, but today all of those things are converged onto a phone. The industrial PC is going to be like the smartphone, and you’ll have an app store where you can download hardware and software for many different functions.”

SIs Can Lead Factories to Industry 4.0

SIs have an opportunity to be at the forefront of the transformation, and to bring the industry into the future by providing integrated systems using industrial PCs from Intel® partners, such as Axiomtek.

A good place for SIs to start is by providing solutions that maximize the investment, such as reducing waste, enhancing product quality, or improving factory equipment uptime. “SIs have to make sure that there’s a clear ROI, a path to make the solution cost-effective. They also need to focus on operational metrics, and verify cybersecurity so companies know they’re not opening themselves up to risk,” says Berniger. “Critical projects often involve optimizing production by improving maintenance or quality assurance.”

For example, while Industry 3.0 dictated a set maintenance schedule, such as replacing parts A, B, and C after a set amount of time, Industry 4.0 uses predictive maintenance. By connecting machine parts to edge technology for real-time intelligence, factories can avoid potential production shutdowns.

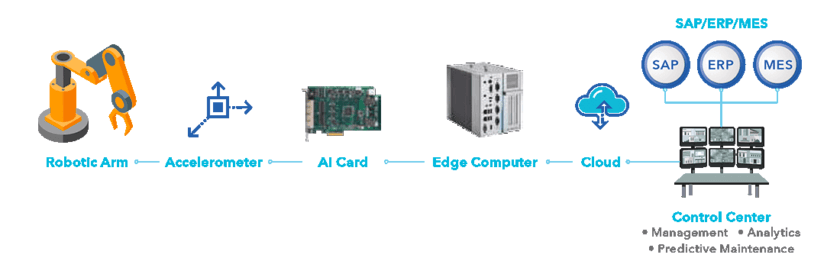

The latest generation of industrial PCs enables this approach by supporting new levels of intelligence and connectivity. For example, the IPC964-512-FL can be outfitted with an AI card to supplement the on-board Intel® Core™ processor (Figure 1).

Another smart solution SIs can provide for industrial PCs is better quality control, enabled by connecting cameras that can replace human eyes for visual inspections. A well-known tire manufacturer, for example, was experiencing an increase in customer complaints from defective tires. Not only was the company’s reputation suffering; it was incurring rising labor and transportation costs from the return of defective tires, cutting into the bottom line.

The company deployed a solution using computer vision and AI, optimized by the Intel® Distribution of OpenVINO™ toolkit and running on an IPC based on Intel technology. In just six months, tire returns dropped from 6,000 to a few dozen. Since the solution is highly scalable, the manufacturer has deployed it to additional production lines for inspection tasks.

“Human eyes are not made to look at the same object for eight hours a day, five days a week,” says Berniger. “But a camera connected to an IPC is very good at that (Video 1). When it’s deployed, we see detection rates going from 80 percent to 99.9 percent, with very few false positives. And the speed increases, in some cases cutting inspection time from a minute down to one to five seconds, depending on the job. Machine vision can detect defects and improve quality assurance for everything a factory makes or ships, helping it save money. Waste is very costly.”

IPCs Bring SIs into the Future, Too

Industrial PCs not only bring manufacturing into the future, they also keep SIs relevant. Gone are the days when SIs could simply bank on having a specific set of capabilities, says Berniger.

“You need to differentiate yourself and add value,” he says. “My boss likens it to two body shops. They may have different levels of craftsmanship, but at the end of the day they both fix the scratch on your car. But if one body shop starts offering value-added activities and solutions, they’re no longer just a body shop; they’re an automobile expert.”

SIs who embrace the capabilities of industrial PCs become the experts that manufacturers need, meeting customers where they are, expanding their capabilities, and becoming their expert guides to Industry 4.0.