PDM Keeps Smart Factory Robots on the Move

Manufacturers rely on predictive diagnostic maintenance (PDM) to reduce downtime and costs by ensuring production machinery is running in optimal condition, solving problems before they happen. But what about the robots that work inside and alongside these machines, performing welding, assembly, inspection, and other precision tasks?

With more than 2.7 million industrial robots in factories around the world, it’s not surprising that PDM has become an essential requirement for these systems. While regularly planned maintenance helps, manual processes can’t identify all problems or ensure that a robot is working within spec.

“Just like any other asset on the production line, robots need predictive maintenance. But factory managers may not know how to diagnose or predict when a robot may have a problem or be on the verge of going down,” says Kurt Chen, Project Manager at NEXCOM.

Though it’s sorely needed, developing an automated, AI-based predictive maintenance solution for robots is complex and challenging. That’s partly because robots don’t necessarily run consistently, as conveyor systems, overhead cranes, or packing machines do.

Their complex, three-dimensional movements – which can include starting and stopping at odd intervals and rotating on multiple axes in dozens of positions – emit greater and more complex vibrations than other machines. That can lead to problems like loose screws, worn gears, overheated motors, or even collisions with other robots. In addition, robots are customized with special tools and configurations susceptible to failure.

Standard factory PDM models for quality assurance, for example, typically lack the AI models needed to accommodate robots’ unique and varied tasks.

The system offers advice about problems that could occur and recommendations for preventing them.

Ideal for Smart Factories; Ideal for SIs

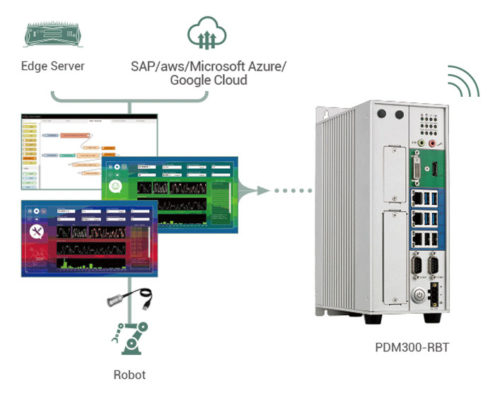

NEXCOM, a global provider of industrial computing and predictive maintenance solutions, solves these challenges. Its PDM300-RBT Intel® IoT RFP Ready Kit addresses a wide range of robot-specific challenges, and offers systems integrators (SIs) an easy way of customizing the solution to individual factory operations (Figure 1).

The NEXCOM kit includes four primary elements:

- A computer vision system running on the Intel® OpenVINO™ Toolkit, which performs LED object detection to accurately guide the robot.

- A predictive maintenance vibration kit with sensor arrays that operates in a similar fashion, alerting factory operators to abnormal vibrations before robots break down.

- A secure Intel® processor-based gateway that sends detailed information about robot performance to the cloud, where factory managers can slice and dice the data to track trends.

- A seven-axis demonstration robot that runs the predictive maintenance software to perform common factory tasks. SIs can use it for critical proof-of-concept trials at client facilities.

The NEXCOM solution can detect the output and health of many kinds of robots, including delta robots, selective compliance assembly robot arms (SCARA), and articulated robots. After a computer vision camera and vibration sensors capture baseline data about a robot’s normal operations, the software monitors ongoing patterns to detect anomalies. Its three-dimensional capabilities allow it to inspect robot performance from multiple angles and pinpoint a host of potential issues.

Standalone, magnetic sensors attach to any surface near a robot, which eliminates the need for permanent fittings. And its adaptive AI can handle PDM requirements in as little as three minutes to begin formulating patterns for a specific robot chain.

“We have large computing engines doing the analysis and can get a lot of information from every sensor. The system offers advice about problems that could occur and recommendations for preventing them,” Chen says.

A Path to Smarter Factories

Out of the box, NEXCOM’s PDM kit allows factory managers to address many issues that plague robots. It also gives SIs the tools they need to solve customers’ more specific problems. The result could be a sea change in the way factories manage robots.

For plant managers, real-time alerts will nip problems in the bud, while cloud-based analytics will improve decisions about future operations and purchases. For SIs, a wealth of pre-loaded information speeds the development of custom solutions and facilitates expansion to new markets.

As more manufacturers adopt robot PDM solutions, machine learning systems will sweep in more data, broadening knowledge about the workings of these complex machines. SIs and factory managers will find new ways to make their robots more capable, responsive, and resilient, avoiding problems and outages and making factories more efficient.