Build an Autonomous Mobile Robot in One Day

Autonomous mobile robots (AMRs) offer one of the highest opportunities for growth in factory automation. More than 4 million of these machines are projected to work in warehouses by 2025.

And that’s just one application for these clever bots. AMRs can also perform cleaning duties, locate and transport specific items to specific places, explore rough terrain, and interact with humans.

But the robot revolution won’t happen without human help. Building an AMR requires expertise in the complex fields of AI, machine vision, and robotics. Developing this expertise can take a large investment of time and money—or engineers can take a shortcut by using off-the-shelf tech.

Machine Vision in a Day

One good example is the RoboMaker Pro Kit from UP. As illustrated in Figure 1, it provides a ready-to-roll AMR chassis that comes with:

- An Intel® RealSense™ D435 camera for 3D vision

- An Intel® Movidius™ Myriad™ X VPU for vision processing

- ROS2 and Ubuntu 16.04 operating systems

- Support for AWS RoboMaker and the Intel® OpenVINO™ Toolkit

- Power distribution, servo motors, batteries, and Wi-Fi

“Using the Kit, developers can build an end-to-end solution demo or PoC right out of the box.” —@danielecleri, @aaeon

“Using the Kit, developers can build an end-to-end solution demo or proof of concept (PoC) right out of the box,” said Daniele Cleri, an AI and IoT software architect at the company. According to Cleri, developers can create a machine vision application in a single day, and produce a working demo in days.

Key to this quick dev cycle is the kit’s use of AWS RoboMaker. Cleri pointed out that a key requirement for an AMR is the ability to see in 3D and make autonomous decisions. But without the right tools, the process of testing and developing these algorithms can be painfully slow.

AWS RoboMaker solves this problem by providing a simulation environment that replaces physical tests. Tasks such as obstacle avoidance and area mapping can be simulated in RoboMaker to quickly iterate design ideas. Once optimized, the algorithms can be ported to the robot.

This direct simulation-to-reality workflow is enabled by the Intel OpenVINO Toolkit, which translates RoboMaker algorithms into code that the kit can use. Intel® and AWS worked together to ensure a seamless integration between the technologies.

Another benefit of the AWS platform is the ability to perform fleet management using AWS IoT Greengrass. This simplifies control and synchronization of hundreds or even thousands of robots, and aids in lifecycle management.

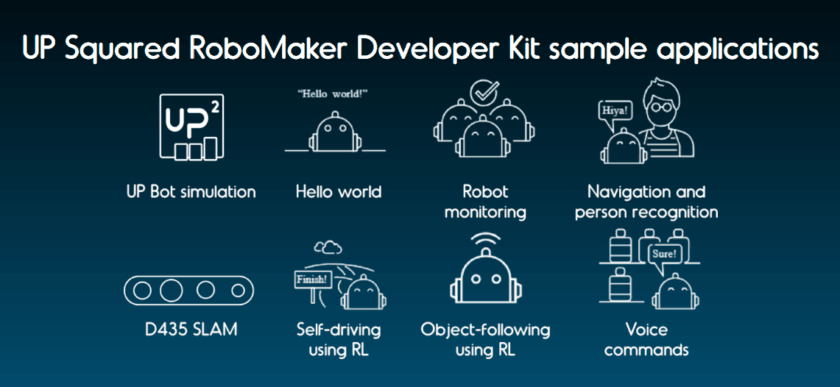

To further streamline development, the kit comes with a variety of sample applications. These include vision, inference, navigation, and compute (Figure 2).

A Range of Use Cases in Development

In addition to developing warehouse robots, AMRs can be trained using OpenVINO to perform other assignments such as security. “Inference applications can be used to teach a robot to roam a defined space and observe people for patterns that may indicate suspicious activity,” said Cleri. The response to such behaviors can be automated, or forwarded to security officers to review and act on.

Much of development currently around the UP Squared RoboMaker Kit and Cogniteam software is taking place at universities, including Ben-Gurion University and Bar-Ilan University, as well as institutions like Mitsubishi Research Lab. “We’re fortunate to have close collaboration with Intel® and other organizations,” said Cleri.