How Building Automation Powers Energy Efficiency

In the run-up to the 2008 Beijing Olympics, the city’s poor air quality overshadowed the news about its opening ceremonies. In response, the central government took strong measures to address the problem. For example, high-polluting vehicles were banned and alternate-day driving rules were established. Even factories and power plants were shuttered for the duration of the games.

A decade later, the country has moved well beyond a day-by-day approach to tackle its serious pollution challenges. The government is driving an internal renewables transformation—gaining recognition as a global leader in solar and other green energy products.

This can be seen in its considerable investments in a range of technologies. In 2016 China held more than 150,000 renewable energy patents—about 29 percent of the global total.

Despite these investments, China leads the world in energy use and greenhouse gas emissions. In response to these growing challenges, the central government developed a “Strategic Action Plan for Energy Development.”

Innovation provides the foundation of this strategy, to speed adoption of clean, efficient, safe, and sustainable modern energy systems. And government policies are changing a culture of consumption.

Increasing energy efficiency in the building sector has great potential for achieving policy goals while lowering operational and consumption costs. Buildings account for 20 percent of the country’s total energy use and 25 percent of greenhouse gas emissions.

This is triggering the need for automated monitoring and control of power distribution systems in communities, and in buildings of all types, including office towers, factories, schools, and more.

But buildings are powered by a host of legacy energy sources and systems, which create substantial challenges in managing, controlling, and lowering consumption. Traditional energy-saving technologies create more bottlenecks than solutions.

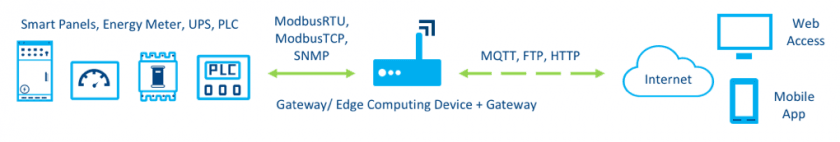

And there are no unified standards, meaning power systems are incompatible. Energy meters, smart panels, programmable logic controllers (PLCs), and uninterrupted power supplies (UPSs) all use different data structures and protocols.

From Building Automation to Energy Efficiency

SBS Science & Technology Co., Ltd. is tackling these challenges and creating new opportunities with its Energy Efficiency Management Solution. The system is typically deployed in industrial automation and IoT control applications such as smart grid, energy management, and others.

It collects and processes data from a variety of power distribution systems, such as electric meters, switch cabinets, and circuit breakers. With data analytics at the edge and the cloud, both real-time and historical data is at hand for monitoring status and controlling operations via a management portal or mobile app.

An example is one company that has deployed the SBS solution to manufacture, install, and operate distribution cabinets for factories. In the past, engineers manually checked on equipment status and collected consumption data to record and analyze system health.

With the SBS solution, the company has been able to eliminate these labor-intensive and error-prone operations.

- Smart gateways automatically record and upload equipment and energy consumption status.

- Reliable alarm management enables real-time response to equipment changes and anomalies.

- Continuous, cloud-based analytics provides a reference for engineers.

These capabilities enable the company to benefit from comprehensive asset management. For example, it tracks historical trends and equipment account information to enable preventive asset management and equipment maintenance planning.

As a result, the customer has significantly cut labor costs and increased operational efficiency while also reducing consumption.

The core of the Energy Efficiency Management solution is a ruggedized edge gateway that provides the systems connectivity and processing power. It collects and normalizes energy device data over various protocols such as Modbus and SNMP. And it connects to the cloud for data storage and analysis via standard networks such as 4G, Wi-Fi, or Ethernet as shown in Figure 1.

“A single smart gateway can collect data from all the applicable energy equipment simultaneously, which saves on hardware and lowers cost,” said Bo Jiang, Vice Chief Engineer of SBS. “It then performs data optimization and compression according to specified formats, and stores that data for encrypted transmission.”

Balancing Demand and Supply

The SBS solution includes essential functions for controlling energy consumption:

- Real-time analytics of system status, including temperature, humidity, voltage, power consumption, and other critical building environmental factors.

- Intuitive map navigation for visibility into equipment operation and energy consumption, via a browser or mobile client.

- Configurable alarms enable immediate response to equipment problems as they occur.

- Preventive maintenance through automated work orders to avoid unscheduled downtime.

“These smart energy capabilities automate equipment monitoring while balancing demand and supply. The centralized data center combined with IoT edge devices play a key role in system optimization, dispatching, and decision-making,” said Jiang. “Intel® technology provides substantial value to our product development. We continually benefit from the powerful compute capability and AI compatibility of Intel processors.”

The SBS team is experienced in developing Intel-based platform embedded computers and its open architecture simplifies system expansion and upgrades. “We can develop reliable solutions that meet green standard embedded computer platforms, while reliably operating in harsh industrial environments,” concluded Jiang.

Industrial IoT technologies are putting cities, businesses, and manufacturers on the road to achieving China’s energy directives. Innovative solutions enable them to not just reduce consumption but to lower costs and improve operational efficiencies.