Cutting Costs and Emissions with Smart Energy Services

Climatologists fear recent wildfires and heat waves across northern latitudes are an indication of what’s to come without rapid and forceful response to climate change. But as we’ve learned in the past few decades, slowing global warming requires much more than just “going green.” It means incentivizing energy producers and consumers where they’ll feel it today: their wallets.

For instance, building HVAC systems and fans account for 10 percent of global electricity consumption. So cost-sensitive energy stakeholders may want to start looking for opportunities in areas with extreme climates.

How SES Saved 20 Percent and 15 Million Miles of Emissions

Building operations teams must find ways to lower high energy bills while helping management operate and maintain the facility in a more sustainable manner. To do so, many turn to low-Capex programs such as the Smart Energy Service (SES) from DOTS Tech Systems, an IoT services provider specializing in development of connected applications.

Traditionally, existing facility systems and equipment operate manually irrespective of demand. Through SES, the DOTS team conducts a detailed survey to come up with the most technically feasible and economically viable solutions. The prime objectives are to optimize energy consumption in a way that does not disturb the operations, improves indoor environmental quality, and enhances occupant comfort. DOTS uses the latest IoT sensors, gateways, and an enterprise grade Smart Energy Services cloud-hosted platform in a SaaS model.

This IoT-driven solution is offered as a subscription service, which benefits many customers where sustainability is top of mind. The DOTS team has already successfully delivered and implemented SES in some prestigious flagship projects from companies such as DP World, Department of Public Works, Empost, HCT, and many more places all over the Middle East.

The cost and #CarbonEmissions savings enabled by #SES are impressive, but equally as impressive is the support to enhance equipment uptime by data-driven condition #MaintenanceManagement. @dotstechsystems via @insightdottech

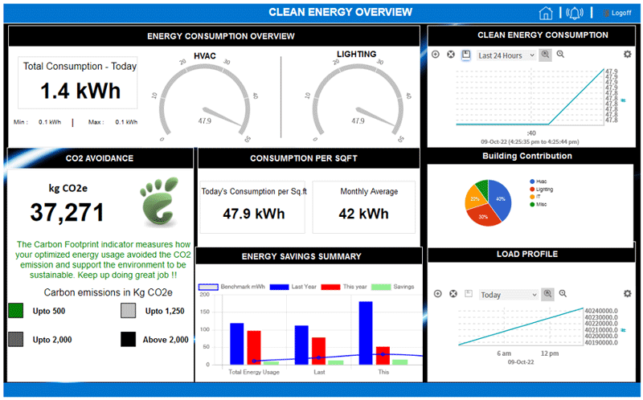

In one customer example, DOTS integrated the building systems using optimum last-mile connectivity protocols and had SES up and running at the facility where it measured the building’s energy profile in real time, logged activities, and provided access to energy, maintenance, and environmental metrics to service subscribers. This information was then displayed in an intuitive dashboard that allowed DOTS and client-side stakeholders to examine real-time and historical performance trends as they diagnosed the cause of the inefficiency (Figure 1).

In that example, the culprit was the facility’s HVAC plant, a large evaporative cooling system that’s common in buildings of more than 100,000 square feet but can be simultaneously energy guzzling and wasteful if not managed properly. After pinpointing the cause, the DOTS team—in collaboration with the building operations team—used the SES analysis to implement various energy conservation measures (ECMs), including:

- Implementation of SES auto alerts on performance deviation

- Installation of Chiller Plant Manager for demand-based auto operations

- Replacement of 3-way to 2-way CHW Valves

- Installation of VFDs on chilled water pumps with index point DP sensor

- Installation of motion/occupancy-based sensors for lighting

- Installation of CO sensors for car park ventilation fan operation

- Shifting from manual to completely automated operations with appropriate setpoints

- Operating schedule and night setback modes for various equipment/systems

- Peak Energy Demand Response and operational optimization driven by smart algorithms

- Continuous commissioning on major equipment and systems

- Energy monitoring and targeting

- Training and awareness sessions, and CSR alignment sessions

In the reporting period after these changes were implemented, the facility exhibited energy savings of 8,415 Megawatt Hours (MWh) and 5,470 tons of CO2 emissions reduction per year. That represented a 20 percent cost savings for the building, and the removal of greenhouse gas emissions that would be generated by driving the average passenger car 14,549,329 miles.

Cutting Costs & Carbon Emissions in the Real World

The cost and carbon emissions savings enabled by SES are impressive, but equally as impressive is the support to enhance equipment uptime by data-driven condition maintenance management.

SES software runs in the cloud as well as on Intel® Next Unit of Computing (NUC) 10, 11, or 12 mini-PCs at the edge. DOTS deploys a multiprotocol edge firmware on the NUCs, which feature Intel® Core ™ processors and provide ample performance to communicate with equipment sensors and run edge analytics. Execution of control logic happens automatically when there is a deviation in the sequence of operations. Advanced fault detection and diagnosis is also conducted at the NUC edge and processed data is transmitted to the cloud for reporting purposes.

What’s more, DOTS helps make SES a fraction of the cost of competing smart energy systems, being a smart and lean design.

“The firmware we use at the edge is a kind of multiprotocol data exchange system as we work agnostic to any makes of systems we may find at the building’s end,” explains Dheeraj Singh, CEO of DOTS Tech Systems. “We deploy or download that into the NUC, which has the ability to deal with different kinds of drivers and required processing computing powers.”

“By being a multiprotocol data exchange layer at the edge, it does data normalization,” Singh continues. “It’s either a soft integration directly using the protocol, or there might be a range of sensors data and they in turn communicate with the NUC. Then the NUC communicates with the cloud, where we have an advanced analytics engine to process this data.”

DOTS has harvested more than 30 million data points that inform regression algorithms the SES uses to reach energy optimization outcomes. Control decisions based on this analysis are passed back to NUCs at the edge, which relay those commands along with any others related to rules being housed at the edge, on to the endpoint. These control algorithms are customized to cater to the building operational trends. The algorithms also take inputs from the building’s occupancy per area to achieve demand-driven ventilation optimization for the building; this would enable the building to perform efficiently during a peak energy demand scenario.

Smarter Energy Savings: Not an Outlier

DOTS case studies demonstrate just how effective smart energy can be, both for the environment and the economy. And it’s no outlier. In fact, it may be an outlier in the wrong direction.

“It’s a digital transformation program and has shown quite good results for clients,” says Singh. “If they’re paying X, post this program, it will be reduced by 25 to 35 percent based on how the building is managed at the start point. Yes, there is a cost to have this program, however there is a bigger cost in not having this program.”

“Those kinds of value propositions are directly impacting the bottom line as well as supporting us in doing our bit towards the environment,” he adds.

This article was edited by Christina Cardoza, Associate Editorial Director for insight.tech.